Delivering water to properties at higher altitudes poses unique challenges—gravity works against the system, atmospheric pressure is lower, and traditional solutions often fall short. For mountain homes, hillside farms, or elevated industrial sites, accessing underground water takes more than standard equipment. Thankfully, advancements in design and performance have transformed how these systems overcome vertical lift demands. Today’s high-efficiency technology delivers consistent pressure, improved durability, and smarter control, all built to perform where the terrain is toughest.

Overcoming Vertical Distance

Elevation significantly affects how water moves from underground sources to the surface. The greater the lift is required, the harder the system must work to maintain a consistent flow. Basic setups may struggle under these conditions, leading to low output, increased wear, and higher energy consumption. High-elevation systems require specialized configurations designed to handle high density. Modern multi-stage equipment, for example, uses a series of impellers to incrementally increase force. This allows systems to move fluid vertically across hundreds of feet while still maintaining stable delivery. Variable-speed motors are also gaining popularity in these regions, adjusting performance based on real-time demand. These intelligent systems reduce strain, conserve energy, and extend operational lifespan—even when conditions fluctuate.

Material and Design Matter More at Altitude

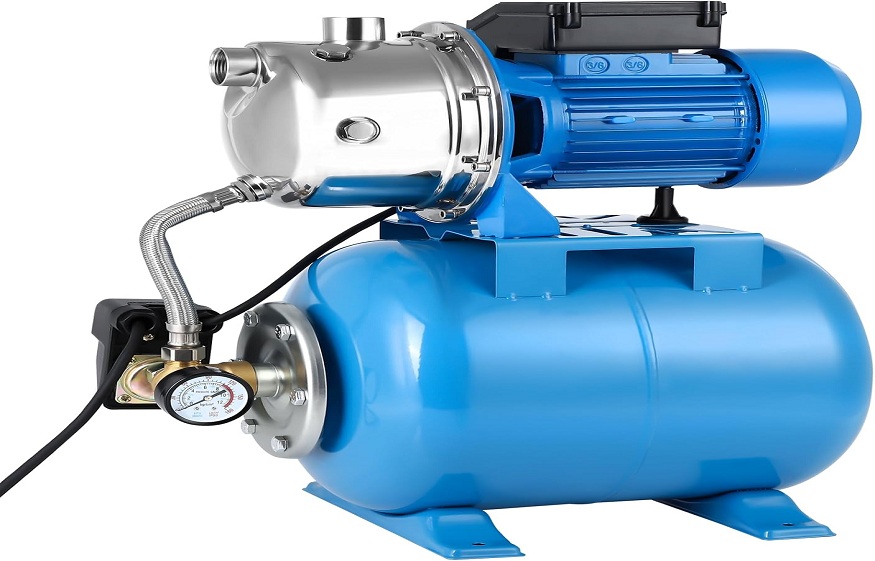

Components used at higher altitudes must endure more than just distance—they must resist environmental wear, handle variable temperatures, and prevent leaks or contamination. Stainless steel and corrosion-resistant alloys are favored for their ability to withstand both mineral-rich groundwater and exposure to the elements. Reinforced piping and sealed electrical connections are also crucial. At elevation, temperature changes and soil movement can stress weak materials and poorly connected joints. An advanced pressure tank for well pump can further balance delivery, especially in freeze-prone areas or when system demand changes frequently. These features prevent unnecessary cycling and provide more reliable control over household or agricultural distribution. Compact, submersible units with built-in sensing are now commonly used in mountainous regions. These designs eliminate the need for bulky external components and can be installed in tighter, sloped areas where access is limited. The reduced footprint makes them ideal for private properties where discretion and minimal disruption are priorities.

Smart Controls Deliver Stability

In areas where power fluctuations are common or where water use varies throughout the day, standard on-off systems often underperform. That’s why smart technology is changing how high-altitude systems are managed. Digital sensors, remote monitors, and app-based controls are now being integrated into modern water infrastructure. These systems automatically adjust output to match demand—scaling up for irrigation during the day and conserving power when only basic household use is needed. Real-time alerts let users know when performance drops or when maintenance may be required. In some cases, data can be sent directly to technicians, minimizing downtime and preventing costly repairs. Remote access also allows users to control flow settings even when they’re not on-site. This is especially valuable for seasonal homes or remote facilities where visual checks aren’t always possible. By automating balance and control, smart systems deliver better reliability at higher elevations where conditions can be unpredictable.

Tailored Solutions for Every Application

No two properties are the same—especially in mountainous regions. Slopes, soil types, water table depth, and climate all influence the type of system needed. That’s why tailored planning is essential. Well drilling contractors often conduct detailed site evaluations to determine the ideal setup, factoring in long-term sustainability, regulatory compliance, and cost efficiency. For example, a hillside vineyard may require a multi-zone delivery system with large storage tanks and booster options to irrigate different elevations. A remote cabin might need a compact, solar-compatible unit that balances reliability with energy independence. And a small business operating above the tree line may benefit from a hybrid design that combines traditional mechanics with high-efficiency electronic controls. Customization ensures the solution not only works today but will continue delivering water efficiently for years to come, even as demand changes or expansion occurs.

Providing consistent water access in high-elevation environments is no longer an unsolvable challenge. With a pressure tank for well pump, precision engineering, and smart control systems, today’s solutions are more reliable, energy-efficient, and adaptable than ever before. Whether you’re maintaining a rugged off-grid homestead, developing a mountainside retreat, or overseeing a commercial operation, the key is investing in a system that’s built for the elevation. That means selecting the right configuration, using high-grade components, and relying on well drilling contractors who understand the unique demands of altitude-based infrastructure. By choosing modern technology designed to overcome steep terrain, property owners gain more than just access to water—they gain peace of mind, lower maintenance costs, and a system that performs under pressure—literally. If your current setup can’t keep up, it might be time to explore smarter, stronger solutions built for the heights.